You need a budget for custom cabinets, but every quote is wildly different. It’s impossible to plan accurately, leaving you worried about overpaying for low quality or blowing your entire project budget.

The cost of a custom cabinet is not fixed. From a Chinese factory, expect to pay $150 to over $500 per linear meter, depending heavily on materials, hardware, and complexity. This factory price is only part of the total cost.

As a furniture manufacturer in Foshan, I see this confusion from buyers like Jacky every single day. They send a design and ask for "the price," but it’s like asking for the price of a car without specifying the model or features. The final cost of custom cabinetry is a mix of many different factors. I’ve seen cabinets of the exact same size have a price difference of three or four times. The key to getting value isn’t just finding the lowest price; it’s understanding what you are paying for so you can balance cost and quality effectively.

You are trying to budget for a project, but without a clear cost structure, you’re just guessing. You need to understand what drives the price to create a realistic budget for your clients.

A custom cabinet’s cost is built from materials, hardware, finish, and labor. A basic melamine cabinet might be $150/linear meter from the factory, while a solid wood one with imported hardware can easily exceed $500/linear meter.

Let’s break down where the money really goes. The final price you are quoted is not just one number; it is a sum of several key components. As a buyer, knowing these helps you negotiate and make smart trade-offs.

- Materials1: This is the biggest variable. A cabinet box made from standard particleboard is much cheaper than one made from furniture-grade plywood. For doors, a simple melamine finish is the most cost-effective, while a high-gloss lacquer on an HDF door is more expensive, and solid wood is typically at the top of the price range.

- Hardware: This is a place where skimping costs you more in the long run. Basic, unbranded hinges and slides are cheap. However, specifying high-quality hardware from brands like Blum or DTC with soft-close features can add $20 to $50 per door or drawer. For a whole kitchen, this adds up but significantly improves the user experience and durability.

- Design & Complexity2: A simple flat-panel door is easy to produce. A complex shaker-style door or one with intricate routing takes more machine time and labor, increasing the cost. Curved cabinets, custom internal organizers, and glass inserts also add to the price.

Understanding this breakdown allows you to tell your supplier, "My budget is X, let’s use plywood boxes but a more cost-effective door finish to meet it."

Is it cheaper to buy cabinets or have them built?

You wonder if stock, pre-made cabinets are the better financial choice. The low upfront price is tempting, but you are concerned about quality, fit, and long-term value compared to custom.

Buying stock cabinets is usually cheaper upfront. However, custom-built cabinets often provide better long-term value by perfectly utilizing space, offering higher-quality materials, and eliminating the need for filler panels and modifications.

This is a classic "pay now or pay later" scenario.

- Stock Cabinets1: These are mass-produced in standard sizes (e.g., 30", 36", 42" wide). Their main advantage is low cost and immediate availability. However, you are forced to design your space around their fixed dimensions. This often results in wasted space, awkward layouts, and the need for unsightly filler strips to close gaps. The material quality is also generally on the lower end, often using thin particleboard and basic hardware.

- Custom Cabinets2: These are made to your exact specifications. Every inch of your space can be utilized effectively. You control the material quality, the hardware, the internal layout, and the finish. While the initial investment is higher, the result is a more functional, durable, and aesthetically pleasing kitchen. For a B2B buyer, custom from an overseas factory can often compete with the price of mid-range domestic stock cabinets but with far superior quality and fit. The key is planning for the longer lead times.

Here is a simple comparison for making your decision:

| Feature | Stock Cabinets3 | Custom Cabinets4 |

|---|---|---|

| Initial Cost | Lower | Higher |

| Space Utilization | Poor to Average | Excellent |

| Material Quality | Basic | Your Choice (Good to Premium) |

| Design Flexibility | Very Limited | Unlimited |

| Lead Time | Immediate | 4-8 Weeks+ |

| Long-Term Value | Fair | Excellent |

How much does it cost for someone to build a cabinet?

You need to account for all costs, not just the product. You are worried about the "hidden costs" of shipping, taxes, and installation that can wreck your budget after the factory invoice is paid.

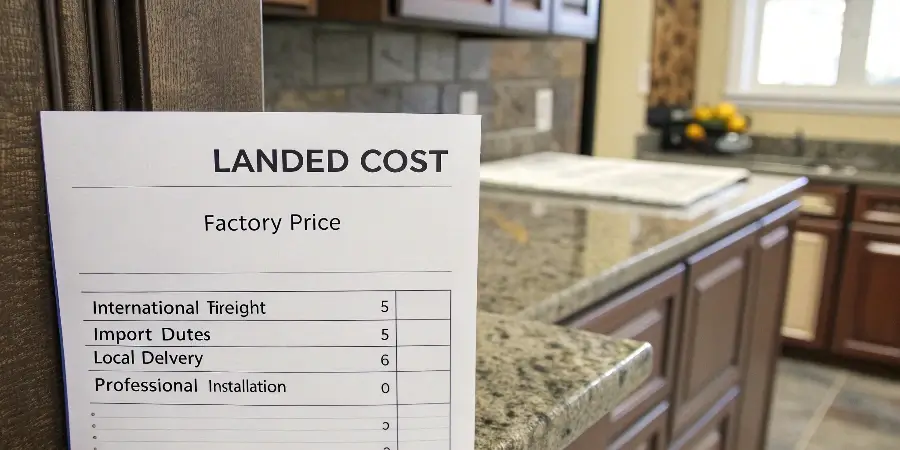

The "landed cost" of a custom cabinet is often 30-50% higher than the factory price. Beyond the factory quote, you must budget for international freight, import duties, local delivery, and professional installation.

I always advise my clients to look at the "total landed cost5." The price from my factory is just the starting point. Getting the cabinet from the factory floor in China to a finished kitchen in Canada involves several other significant expenses that many first-time importers forget to budget for.

- Factory Price (FOB): This is the cost to produce the cabinets. As we’ve discussed, this can be anywhere from $150-$500+ per linear meter based on specifications.

- International Shipping: The cost to ship a container from China to North America can vary dramatically, from $2,000 to over $10,000 depending on market conditions. This cost is spread across all the items in the container.

- Tariffs and Duties6: Your country will charge taxes on the imported goods. This can be a significant percentage of the goods’ value (for example, 10-25%). A customs broker can help you calculate this.

- Local Logistics: Once the container arrives at your port, you need to pay for drayage (port transport), warehousing, and local delivery to the job site.

- Installation: Professional installation is critical for a high-quality result. This labor cost can range from $50 to $150 per cabinet, depending on complexity and local labor rates.

Failing to account for these additional costs is the most common budgeting mistake I see. A reliable supplier should be able to help you estimate these costs to get a true picture of your investment.

Is custom cabinetry worth it?

You are weighing a higher upfront cost against potential benefits. You need to know if the investment in custom cabinets will truly pay off in project quality and client satisfaction.

Yes, custom cabinetry is worth it for projects where maximizing space, achieving a specific design aesthetic, and ensuring long-term durability are priorities. It solves problems that stock solutions cannot.

From a project perspective, custom cabinetry7 is a problem-solver, not just a product. It is absolutely worth the investment when you are facing specific challenges or aiming for a superior result.

Custom is worth it when:

- Space is limited: In condos, apartments, or oddly shaped kitchens, custom cabinets can reclaim valuable inches, providing storage solutions that would otherwise be impossible. This improves the functionality and value of the property.

- A specific look is required: If your design vision involves a unique color, a specific wood grain, or a seamless, high-end modern look, custom is the only way to achieve it perfectly. It ensures design continuity throughout a home.

- Durability is paramount8: For a high-use kitchen or a luxury build, you can specify durable materials like plywood boxes and premium hardware. This prevents issues like sagging shelves and failing drawers, ensuring client satisfaction and protecting your reputation.

While not necessary for every project, custom cabinetry1 provides a level of control over quality, function, and aesthetics that stock options can’t match. For B2B buyers who manage projects with specific design and performance goals, it is an investment that consistently pays for itself.

Conclusion

Custom cabinet pricing is flexible, not fixed. Understanding the cost factors and working with a transparent factory partner allows you to get high-quality, tailored solutions that fit your budget and project goals.

-

Exploring this link will help you understand how material choices impact cabinet pricing and quality. ↩ ↩ ↩

-

This resource will provide insights into how design choices can influence your overall budget and cabinet functionality. ↩ ↩

-

Learn about the limitations of Stock Cabinets to make an informed decision for your renovation project. ↩

-

Explore the advantages of Custom Cabinets to maximize space and enhance your kitchen’s aesthetics. ↩

-

Understanding total landed cost is crucial for accurate budgeting in imports, ensuring you account for all expenses. ↩

-

Exploring tariffs and duties will help you grasp their impact on your overall import expenses, aiding in better financial planning. ↩

-

Explore this link to understand how custom cabinetry can enhance your home design and solve specific space challenges. ↩

-

Learn why durability is crucial for kitchen cabinetry to ensure long-lasting quality and client satisfaction. ↩